- Description

- Inquiry

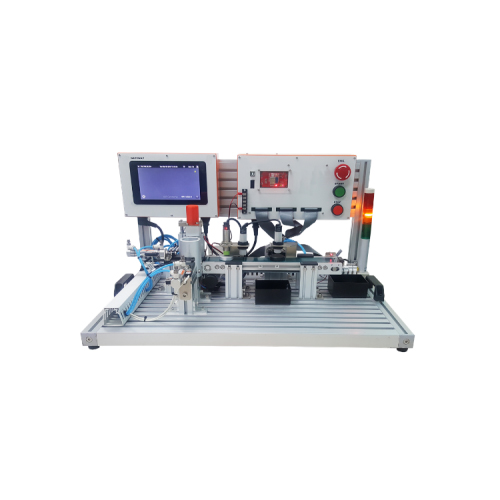

IOT Smart Factory System Trainer SSEDU PCCT-1000

The picture is only for reference

IOT Smart Factory System Trainer

Features:

Smart factory system implementation practice that combines production automation system and Internet of Things (IoT) technology.

Process status and real-time monitoring and remote control using IoT Platform.

Practice sequentially from basic control for each process to smart factory system implementation.

Provides basic / application example programs necessary for various practice.

IoT Service implementation by setting an interlocking control event according to specific conditions using process information of the IoT platform. Production automation supply , processing , transfer , inspection , extraction and storage processes

Technical Specification: Trainer Consist Of :

- 1 x Aluminum Frame

- min. 1 x IOT Gateway Module

- min. 1 x Controller with IOT

- min. 1 x Industrial LED Lamp

- min. 1 x Pneumatic System With conveyor system with its related sensors and actuators Experiments

Production automation process

- Learning the step-by-step process of production automation and how

to operate the entire process using a microprocessor

- Equipment introduction and environment construction

- LED lamp control

- LED control using switch

- Feed cylinder control

- Machining cylinder control

- Extraction cylinder control

- LED lamp control according to material detection

- LED lamp control according to proximity sensor

- Machining motor control

- Conveyor motor control

- Extraction process

- Transfer process

- Machining process

- Supply, processing and transfer process

- Transfer and extraction process

- Production automation overall process operation

IoT Convergence Automation Process

- Real-time monitoring and remote control of process status by fusion of IoT with existing automation process

- Smart Factory Training Equipment

- Building an IoT environment

- Sensor monitoring using IoT

- LED lamp control using IoT

- Cylinder control using IoT

- Motor control using IoT

- Condition monitoring according to cylinder control

- LED interlock control according to sensor detection

- LED interlocking control using switch

- Supply process IoT interlocking control

- Processing process IoT interlocking control

- Transfer process IoT linkage control

- IoT interlocking control of extraction process

- Count monitoring

- Error processing monitoring

- Error Count monitoring

- Realization of Smart Factory using IoT

Accessories

- min. 1 x User Manual

- min. 1 x set of connection cables

- min. 1 x Sample Codes

- min. 1 x Power Cable

-300x300.jpg)

-300x300.jpg)