- Description

- Inquiry

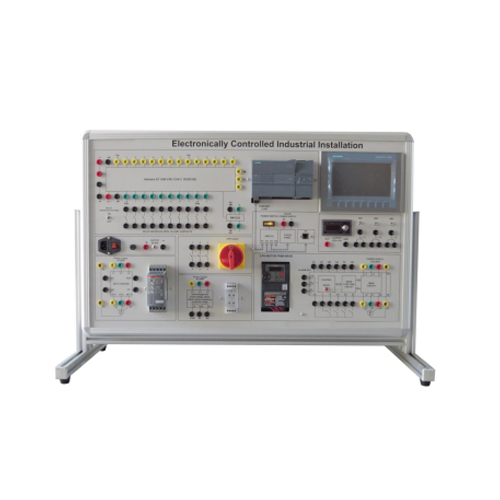

TB220505S10 Motor Control Center Trainer Teaching Equipment Electrical Engineering Training Equipment

I. Product overview

1.1 Overview

This training device includes control objects such as PLC, HMI and other training simulation module. Through related experiments, you can be familiar with the basic use of PLC, programming methods and the use of programming software. Cultivate students’ corresponding knowledge and skills, suitable for teaching and skill training assessment of related majors in higher vocational schools, colleges, secondary vocational schools and technical schools.

1.2 Features

(1) The training platform adopts the aluminum profile column frame structure, the measuring instrument and the training power supply are integrated and installed, and the training circuit and components are combined in a hanging box. The units are flexible, convenient to use, and not easy to damage.

(2) The experimental circuits and devices are fully equipped and can be used in combination to complete the training content of a variety of courses.

(3) The training platform has a good safety protection system. Allow students to conduct experiments independently, which is conducive to cultivating students’ ability to analyze and solve problems.

II. Performance parameters

((1) The capacity of the whole machine: <2KVA

((2) Weight: <120kg

((4) Working conditions: ambient temperature -10℃~+40℃ relative humidity <85% (25℃)

III. Product composition

3.1 Power box

Specific characteristics:

•Current: 50 amps.

•Frequency: 60 hertz.

•Voltage: 240 vac.

•Type of system: Three-phase.Additional characteristics:

•Dimensions: Height 1200 mm, width 800 mm, depth 400 mm.

•Control commands to be carried out: staggered start of 3 motors, rotation change of 2 rotors, start with soft-starter, start with variator. Starts a and b must be done by relay system and plc.

•One (1) 3×50 amp main switch with trip coil.

•One (1) PLC with the following characteristics: With integrated profibus and ethernet interfaces, 1 RS485 port and 3 integrated RJ45 ports, 32 digital inputs 24 VDC; 32 digital outputs 24 VDC;

8 16-bit resolution analog inputs for voltage, current, RTD, and thermocouple; 4 analog outputs with 16-bit resolution for voltage and current; integrated web server.

PLC Brand: Siemens Model: S7-1200

•One (1) HMI touch screen with the following specifications: 15 inches, TFT LCD screen type, connection capacity: Industrial Ethernet network, Profibus, MPI Resolution 1200 x 800 pixels, two USB ports and two SD memory slots.

HMI Brand: Siemens Model: TP1500

•One (1) variable speed drive with communication for industrial Ethernet, 2 analog inputs and 2 outputs of 0 to 10 VDC / 4-20 mA minimum.

Inverter brand: Siemens Model: V20

•One (1) soft starter with control voltage of 24 V AC/DC .

Brand: ABB

•One (1) power supply of 8 Amps minimum.

•One (1) mushroom-type emergency switch with double contact.

•One (1) industrial access point for local wireless network.

•One (1) modem for control and monitoring through mobile phone network.

•One (1) 8 x 10/100 Mbit/s RJ45 switch.

•Independent motor protectors for each type of start.

•AC-3 contactors for power circuit of 2 HP motors, with their respective thermal relays. •Auxiliary relays for PLC control.

•Protections for the command circuits

•LED-type indicator lights (green color, red color, white color), with Ethernet connectivity, for the control commands described above

•NO and NC pushbuttons with Ethernet connectivity, necessary for the control commands described previously.

•Professional-type programming software under a 64-bit Windows operating system for all programmable devices inside the cabinet.

• Programming cables between the PC and the equipment.

• Communication cables through protocol between the equipment.

•Operation manuals.

•It has connection diagrams of all the elements contained in the motor control center.

•Includes induction in the use and management of the equipment.

•Considerations for delivery: All circuits of the motor control center must be wired with their respective channeling, duly identified conductors and terminal blocks.

-300x300.jpg)