- Description

- Inquiry

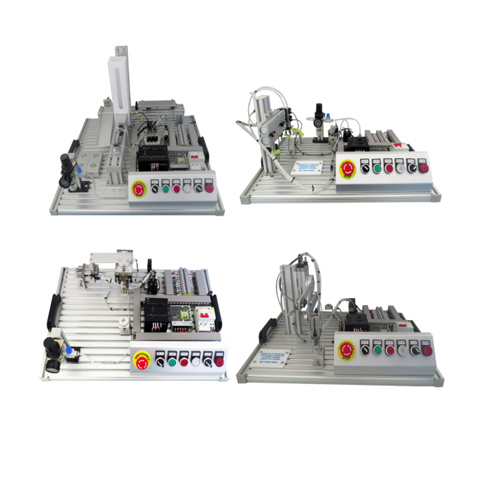

MPS400M Modular Product System Automation Production- Handling System Trainer Didactic Equipment Modular Product System

table of Contents

- Product Overview

1.1 Overview

1.2 Features

- Performance parameters

- Equipment composition

- Practical training content can be completed

- Matters needing attention

- Experimental content

Experiment 1 MCT-MAP-HS01 Sports Training

Experiment 2 MCT-MAP-HS02 Sports Training

Experiment 3 MCT-MAP‐HS03 Sports Training

Experiment 4 MCT-MAP-HS04 Sports Training

- Product Overview

1.1 Overview

This training device system contains 4 motion control systems, so that students have a preliminary intuitive understanding of motion control. Through relevant experiments, the students’ corresponding knowledge and skills are cultivated, which is suitable for the teaching and skill training assessment of related majors in vocational colleges, vocational schools, secondary vocational schools and technical schools.

1.2 Features

(1) The training platform adopts aluminum profile and sheet metal structure, and the structural substrate is installed, which is convenient to use and not easy to damage.

(2) The experimental circuit and device configuration are complete, and the practical training content of various courses is completed.

- Performance parameters

(1) Input power; AC220V±5%

(2) 01 station Dimensions: 680mm×600mm×420mm

02 station Dimensions: 680mm×450mm×300mm

03 station Dimensions: 580mm×450mm×300mm

04 station Dimensions: 680mm×450mm×200mm

(3) Weight: <400kg

(4) Working conditions: ambient temperature -10℃~+40℃ relative humidity <85% (25℃)

- Equipment composition

(1) The gravity feeder accommodates the parts in the column (1). Each part has an asymmetric inner shell and is ejected by a pneumatic cylinder (2). Use a cylinder with a plunger (3) to verify the correct orientation of the parts. After inspection, if the direction is correct, the second pneumatic cylinder (4) moves the workpiece to its final position. A single lift cylinder (5) will move the parts out through the evacuation ramp. If it is not correct, the workpiece will be pushed to the final position by the (4) cylinder, and the alarm light will be on.

PLC model: Omron CP2E-N30DR-D

(2) The module uses a rotary processing device (1) with an internal fixture (2) that moves parts from one location to another.

PLC model: Omron CP2E-N20DR-D

(3)It consists of a rotary loading and unloading device (1) and an external pneumatic gripper (2), which moves parts from one location to another.

PLC model: Omron CP2E-N20DR-D

(4) The module uses a rotary processing device (1) with an internal fixture (2) that moves parts from one location to another.

PLC model: Omron CP2E-N20DR-D

(5) Software U disk

(6) Network cable